The companies’ history of providing bespoke cleaning solutions for customers has led to the development of an extensive workshop and design office where a wide spectrum of engineering solutions are used to solve many cleaning problems. This predominantly concerns the production of hygiene systems as discussed on the previous pages.

However other projects have also been undertaken that have allowed us to use our knowledge and capabilities in other industries. This is certainly the case with the laser guided sheet metal cutting and fabrication service, which we provide to a broad spectrum of local companies. Furthermore other contract manufacturing and bespoke one-off opportunities have arisen such as fire suppression equipment development and prototypes for a local company to the design and manufacture of a fully hydraulic, submergible boat trailer.

In addition to this we have branched into product development and fabrication in the micro brewery sector, this has been led by our Cask Force caskwasher, which in turn has meant brewers asking us to apply our capabilities to other requirements such as pipework, framework and stairwells.

The caskwasher has revolutionised the cask cleaning process and is an asset for any micro brewery. The caskwasher can consistently can clean up to 60 casks per hour (400 series). Peace of mind comes from knowing that any cask that has been through the cleaning cycle is cleaned to the highest standards possible.

Simple, thorough, time-saving and cost effective, the CaskForce caskwasher has an unrivalled range of benefits:

For more information or a demonstration please call Keith Trenton on 01493 688250 or visit www.caskwasher.co.uk

The development of the business has seen the creation of a completely new division designing and manufacturing our Commando Range of specialist independently powered High Pressure Washers.

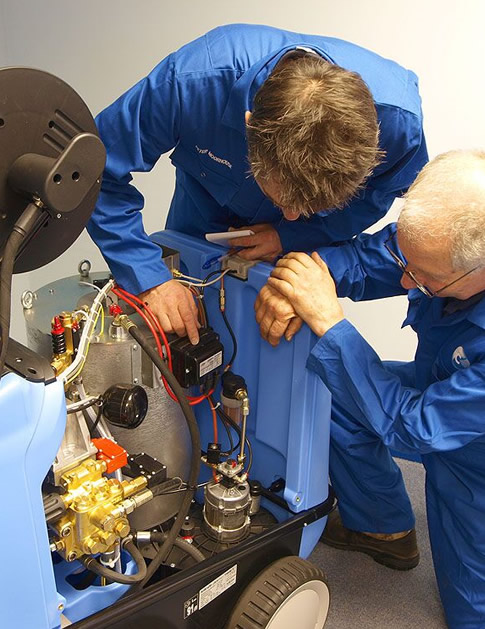

The COMMANDO® Range of high pressure cleaning equipment is the professionals choice. The COMMANDO® range is ideal where arduous duty cycles occur, reliability is important and running costs need to be kept to a minimum. The COMMANDO® machines are easy to operate, powerful, efficient, and are manufactured to BS EN ISO 9001: 2008 accreditation. All of the machines are British designed and built, independently powered and designed to be easily transported to virtually any terrain where power washing or jet washing is required.

The COMMANDO® range of high power cleaning machines is distributed throughout the UK and exported for use in a wide range of industries including civil engineering, agriculture, the military and construction. A commitment to continued innovation and investment in the development of product range by Hugh Crane (Cleaning Equipment) Ltd, means that you can be confident that the COMMANDO® range is always at the cutting edge of design technology.

Once the correct COMMANDO® high pressure cleaning model is selected, full operator training and installation are provided. A comprehensive stores facility ensures immediate supply of high pressure cleaning parts and accessories.

For specialist applications the company offers a technical design service for bespoke equipment.

With over twenty years of manufacturing experience, dedicated design systems, a well trained committed workforce and high quality materials makes the COMMANDO® range of independently powered high pressure cleaning machines your very best choice.

Hugh Crane (Cleaning Equipment) Ltd is a family firm and was formed in 1983 to satisfy a demand for high quality industrial cleaning equipment. The business has continued to expand and the Peterborough branch at Whittlesey was added in early 2000 to satisfy the requests of our clients in the west of the region. During the last few years there has been significant investment within the company at both locations.

The company also manufactures the COMMANDO range of cleaning equipment, which has been designed to meet the needs of the professional sector of the market. New products include Cask Force and Rotawash.

The company is also engaged in the design, manufacture, installation and servicing of industrial cleaning systems together with the distribution of a wide range of chemicals and janitorial equipment for the industrial, commercial and domestic markets across East Anglia and the surrounding region

-

Our Aims:

1. Quality Products

It is our goal to manufacture and distribute products of a reputable quality.

-

2. Competitive Prices

We aim to supply quality products at competitive prices with an after sales service second to none

-

3. Immediate Availability

Most items on this website are available from stock and with daily collections from national carriers it is our aim to supply goods promptly and correctly.

-

4. Unrivalled Service

Prompt and professional service has been the foundation of the company for the past thirty years and it is our aim to continue this, whether it is technical support and advice about our products or the collection of faulty or incorrect equipment.

The company aims to provide the highest quality of service in the industry. This has resulted in achieving two British standards, ISO9001:2015 Quality Standard and more recently ISO14001:2015 Environmental Standard.